Installation and Maintenance Information:

Tools/Materials Needed:

- Safety glasses

- Tape measure or ruler.

- Centerpunch and hammer.

- 1 1/2” hole saw and drill.

- Deburring tool or file.

- Flap disc or sandpaper.

- Welder (not shown).

- Small wire brush.

- Paint.

Installation procedure:

- Locate a suitable position for Hitch Cinch on the receiver tube, mark and centerpunch at center point.

- Bore a 1 1/2” hole in the receiver tube, usually performed with a hole saw.

- Debur the hole with a deburring tool or file.

- Remove any paint or rust on area to be welded.

- Position the Hitch Cinch in the hole, tack weld.

- Temporarily install hitch insert to assure proper fit.

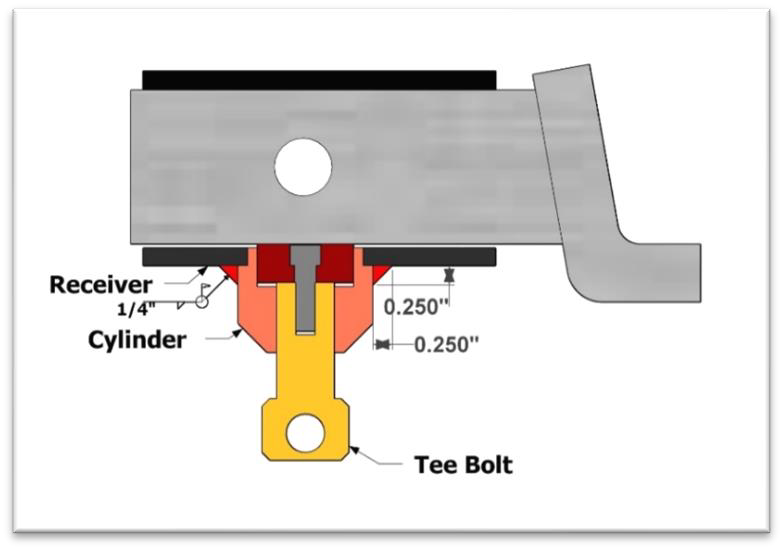

- Weld the Hitch Cinch cylinder to the receiver tube using a 1/4” perimeter fillet weld.

- Touch up paint as needed.

- Install hitch insert and pin, then tighten tee bolt to 60 foot pounds of torque.

Maintenance Information:

Periodically spray penetrating oil around the piston inside of receiver and externally around tee-bolt threads.

It is recommended that an insert is kept insalled and tighened with the Hitch Cinch at all times.